Food & Beverage

Automation solutions for greater product quality and system efficiency

FOOD & BEVERAGE

Food & Beverage applications depend on controls and automation to monitor process variables, provide data, and assist with regulatory compliance. GTH has been providing instrumentation and solutions to this market for much of our 90 years. We specialize in automation, on-site programming support, instrument calibrations, and UL control panel modernization. Our engineers are also trained in ISA and FDA standards as they apply to these applications.

APPLICATIONS WE SERVE

![]() Machine Control

Machine Control

Machine control is more critical than ever. Modern systems are more efficient and reliable, minimizing the change of downtime. We can automate and update your controls and software to help you do more, with less!

![]() Thermal Processes

Thermal Processes

Whether you are using electric or gas heat, we can retrofit your equipment to work more efficiently. We are also familiar with regulations around safety and emissions to ensure you stay compliant.

![]() Data Analytics

Data Analytics

Collecting, storing, and analyzing data in food & beverage is critical. With SCADA and OEE software, you have access to real-time monitoring and predictive analysis to help you make better decisions for your operation.

AREAS OF EXPERTISE

PLC Modernization

From minimizing downtime to improving security, there are many benefits to modernizing existing PLCs. Our upgrade and migration solutions allow you to upgrade while preserving your maximum hardware and software investment. Plus, with our team of technical field engineers, we are able to assist with the system upgrade if you do not have the necessary personnel. We are also proficient in full scale software conversions, factory acceptance testing, and commissioning so you can be certain the modernization will be completed in a timely manner, with minimum downtime.

System Process Design

Food & beverage processes are as unique as the products being manufactured. Our team of engineers have decades of control & software expertise that we can put to work on new system design and retrofits. Whether you are looking to upgrade an existing process, update your instrumentation, customize a software system, or build an entirely new production line, we can help! With our technical expertise and two UL 508A panel shops, we have also teamed with a number of original equipment manufacturers (OEMs) to create new systems for custom applications.

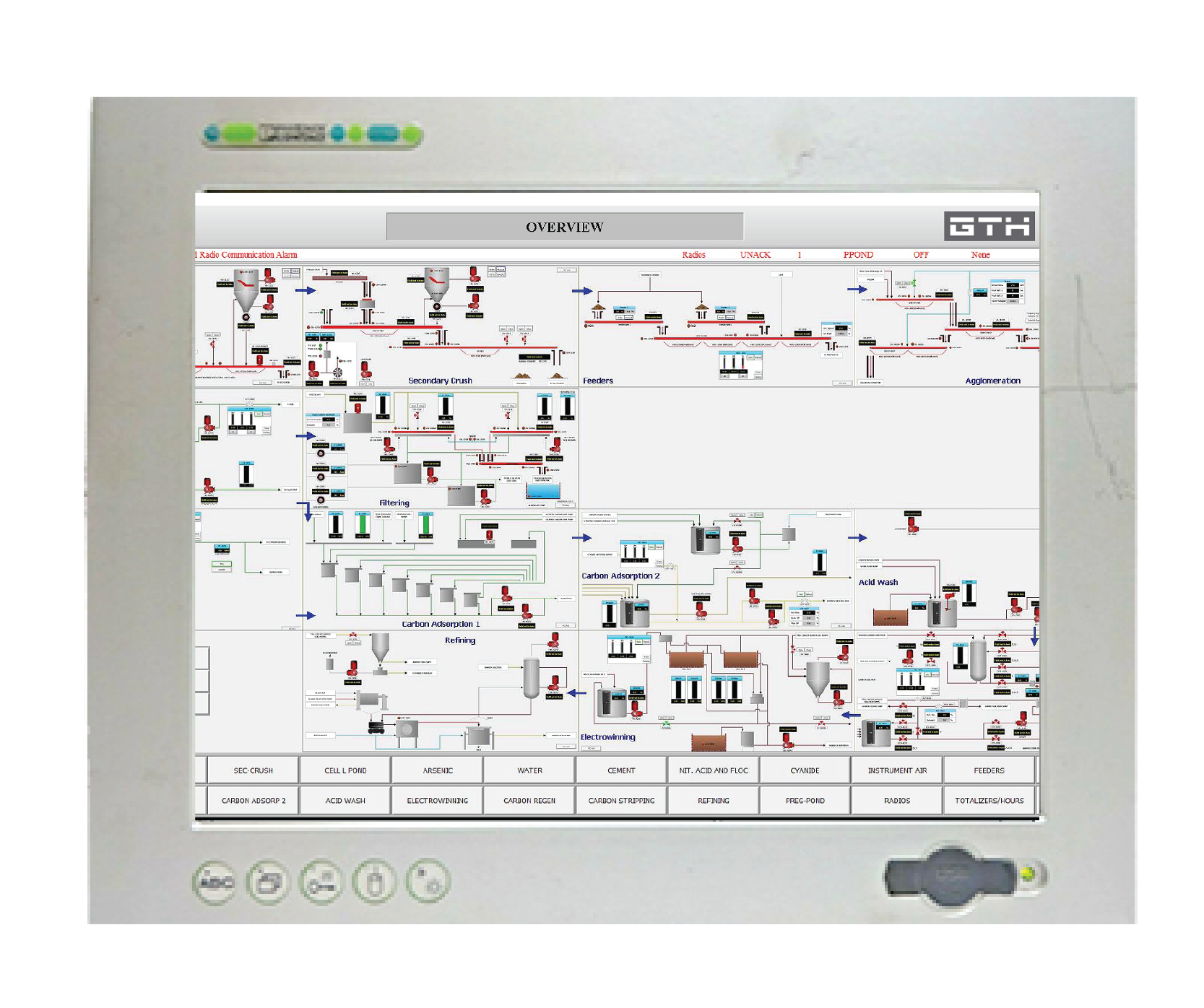

Data Acquisition and SCADA

With the advent of IIoT, data acquisitions & SCADA systems are no longer limited to gathering data points. In food & beverage applications, these systems assist with regulatory compliance such as 21 CFR part 11 and ISA 88. Our Field Engineers are capable of modernizing systems to improve system efficiency and provide greater data visibility. With Asset Performance Management (APM), users are able to monitor system performance, access predictive maintenance, and track reliability across the facility. Modern software also allows for increased remote access capabilities and reporting so your data is both visible and usable in real-time.

FEATURED PROJECTS

Combustion System Upgrade

A large food manufacturer in California came to GTH to upgrade the antiquated combustion system on one of their process ovens to meet new AQMD standards. They also wanted to update their flame safety devices and add an HMI interface to modernize their process.

Corporate Headquarters

1605 E. Gene Autry Way

Anaheim, CA 92805

Ph: 714-939-7100

Manufacturing Headquarters

8565 Double R Blvd.

Reno, NV 89511-2270

Ph: 775-356-7401